Global Ceramic Fiber Market – Analysis and Forecast (2026-2035)

Industry Insights by Type (Refractory Ceramic Fiber, AES Wool), by Product Form (Blanket, Board, Paper, Module), by End-User (Refining & Petrochemical, Iron & Steel, Power Generation, Aluminum)

| Status : Upcoming | Report Code : VRCH2037 | Industry : Chemicals & Materials | Available Format :

|

Global Ceramic Fiber Market – Analysis and Forecast (2026-2035)

Industry Insights by Type (Refractory Ceramic Fiber, AES Wool), by Product Form (Blanket, Board, Paper, Module), by End-User (Refining & Petrochemical, Iron & Steel, Power Generation, Aluminum)

Ceramic Fiber Market Overview

Ceramic fiber is composed of long flexible, interwoven fibers that are manufactured by the process known as ‘spun’ which yields a lightweight, strong, and durable product. This fiber is also known as high-temperature insulation wool (HTIW). These fibers are made of aluminosilicate materials that are controlled with the help of high-temperature furnace melting and fiberizing process. The global ceramic fiber market is to progress at a considerable rate during the forecast period, owing to the increasing demand of technologically advanced, lightweight, less toxic, and renewable products in the market.

The typical application areas of this fiber include refining and petrochemical, reformer and pyrolysis furnaces, gaskets and expansion joints, tube seals, high-temperature pipe, duct, and turbine insulation, and various others.

Ceramic Fiber Market Segmentation

Insight by Type

On the basis of type, the ceramic fiber market is segmented into refractory ceramic fiber (RCF), AES Wool, and others. Among these, the RCF type category holds a larger share in the market, due to the increasing demand for low-cost, low heat storage, high thermal stability fiber. However, AES wool type category is anticipated to register the highest growth in the market during the forecast period, which is attributed to its properties including low bio-persistence and better characteristics.

Insight by Product Form

Based on product form, the ceramic fiber market is segmented into the blanket, board, paper, module, and others. Among all these, the blanket category is anticipated to hold the largest share in the market, which is majorly attributed to the increasing demand of insulation material from different industries including metal, shipping, automobile, and space. Though, the fastest growth is projected to register by module category, due to their suitability at different temperature ranges and design versatility.

Insight by End-User

Based on end-user, the market is segmented into refining and petrochemical, iron and steel, power generation, aluminum, and others. The refining and petrochemical industry segment is the major consumer of this fiber in the market. The demand is majorly fueled by the increasing need of lowering operating cost, lowering energy use in furnace linings, walls, and roofs, increasing reliability, and others, which is driving the growth of the ceramic fiber market. In this industry, this fiber is commonly used in boilers and fired heaters, which offers efficient solutions for energy requirement in the industry.

Ceramic Fiber Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2018–2023 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025 - 2030 |

|

Market Size in 2023 |

$xx.xx Billion |

|

Revenue Forecast in 2030 |

$xx.xx Billion |

|

Growth Rate |

CAGR xx.xx % |

|

Segments Covered in the Report |

By Type, By Product Form, and By End-User |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

Ceramic Fiber Market Growth Drivers

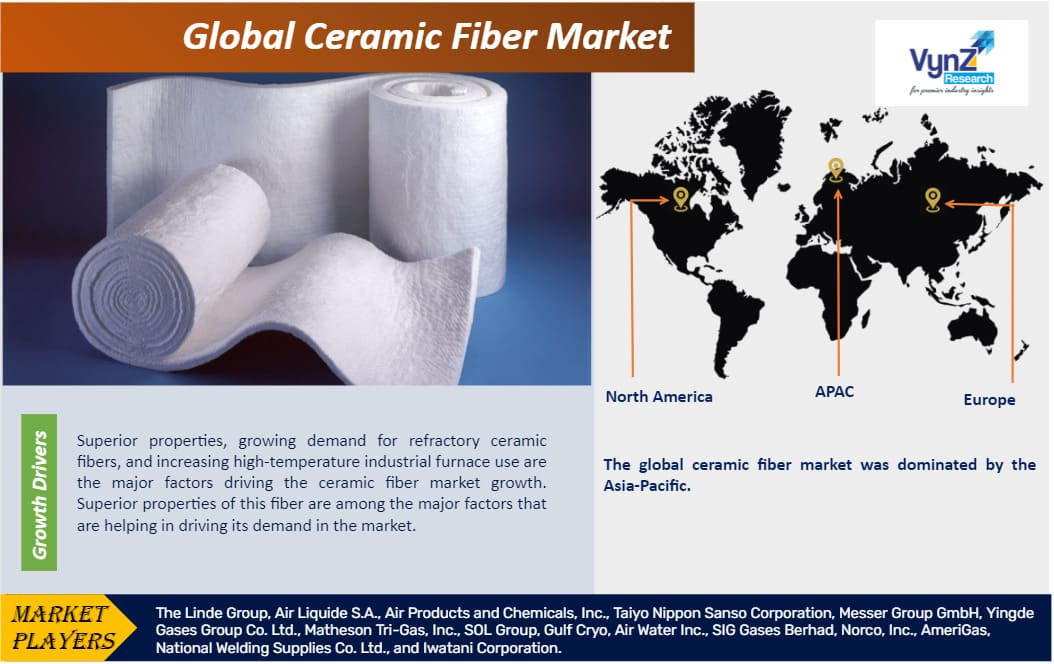

Superior properties, growing demand for refractory ceramic fibers, and increasing high-temperature industrial furnace use are the major factors driving the ceramic fiber market growth. Superior properties of this fiber are among the major factors that are helping in driving its demand in the market. Some of the properties include low thermal conductivity, low heat storage, thermal shock resistance, high tensile strength, easy installation, sound absorption, no binder, no dry out time required, and others. Also, this material can be used with temperature ranges from 1000°F (538°C) to 2600°F (1425°C), resulting in increasing demand for various applications.

Ceramic Fiber Market Challenges

High cost of production and limited availability are identified as a major challenge in the ceramic fiber market, which can potentially hinder the market growth. The fixed capital cost of manufacturing this fiber is high and cycle time is slow. Costs can fluctuate on how much is being produced per unit of time. The price can be lowered by producing the fiber with much less capital requirement at low sales volume. All these factors are posing a challenge in market growth.

Ceramic Fiber Market Industry Ecosystem

The manufacturing of these fibers includes three steps including preparation of bulk, preceramic material to spun; and then spinning the bulk material into a green fiber; and finally heat-treating the spun green fiber to convert this into the ceramic fiber. The most effective way to lower down the costs of these fibers is to increase the production volume, as all other efforts to reduce fiber cost will have very less impact as compared to increases production volume.

Ceramic Fiber Market Geographic Overview

During the forecast period, Asia-Pacific is anticipated to witness the highest growth in the ceramic fiber market, owing to the growth of various industries such as automotive, construction, manufacturing, and other industries. Along with that, the growing investment in the research and development to encourage the use of less-toxic products in the region are also contributed towards the increasing demand for the product in the region.

Ceramic Fiber Market Competitive Insight

Unifrax I LLC manufactures insulation products. The Company offers chopped and unchopped bulk fiber, marine blanket, thermal insulation modules, and fire protection products. Unifrax I markets its products worldwide.

Morgan Advanced Materials plc is a company which manufactures specialist products, using carbon, advanced ceramics and composites. The group is headquartered in Windsor, United Kingdom

Some of the major players operating in the ceramic fiber industry are Unifrax I LLC, Luyang Energy-Saving Materials Co., Ltd., Morgan Advanced Materials Plc, Ibiden Co., Ltd., Fibrecast Inc., Yeso Insulating Products Co. Ltd., Nutec Fibratec, Isolite Insulating Products Co. Ltd., Ceramsource, Inc., Pyrotek Inc., and ADL Insulflex Inc.

Recent Developments by Key Players

Morgan Advanced Materials and Penn State University have signed a new five-year Memorandum of Understanding, to further enhance their partnership. The agreement is focused on research and development in silicon carbide (SiC) crystal growth, for the wide band gap semiconductors fast growing sector.

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverable

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Ceramic Fiber Market