Global Machine Vision Market – Analysis and Forecast (2025–2030)

Industry Insights by Offering (Hardware, Software), by Product (PC Based, Smart-Camera Based), by Application (Quality Assurance and Inspection, Positioning and Guidance, Measurement, Identification), by End User (Automotive, Pharmaceuticals & Chemicals, Electronics & Semiconductor, Pulp & Paper, Printing & Labeling, Food & Beverage [Packaging and Bottling], Glass & Metal, Postal & Logistics, Others)

| Status : Published | Published On : Jan, 2024 | Report Code : VRSME9030 | Industry : Semiconductor & Electronics | Available Format :

|

Page : 165 |

Global Machine Vision Market – Analysis and Forecast (2025–2030)

Industry Insights by Offering (Hardware, Software), by Product (PC Based, Smart-Camera Based), by Application (Quality Assurance and Inspection, Positioning and Guidance, Measurement, Identification), by End User (Automotive, Pharmaceuticals & Chemicals, Electronics & Semiconductor, Pulp & Paper, Printing & Labeling, Food & Beverage [Packaging and Bottling], Glass & Metal, Postal & Logistics, Others)

Machine Vision Market Overview

The market for machine vision is expected to reach USD 14.8 billion by 2030, expanding at a CAGR of 6.2% over the forecast period, from USD 9.85 billion in 2023. The demand for quality inspection and automation in numerous industrial verticals is on the rise, as the need for vision-guided robotic systems in a variety of sectors, including the chemical, packaging, pharmaceutical, food & beverage, and automotive.

Machine Vision Market Segmentation

Insight by Offering

The global machine vision market is separated into hardware and software, based on offer. The hardware category dominated the market in 2021, and during the forecast period, it is projected to increase more quickly.

Insight by Product

The global machine vision market is divided into two categories based on product: PC-based and smart-camera-based. The PC-based category held the largest market share in 2021, and it is expected to continue dominating the industry throughout the study period. However, during the projected period, the demand for smart camera-based systems is projected to increase at the quickest rate in the coming years. This is because 3D imaging uses cameras more frequently now.

Insight by Application

The positioning & guiding, identification, measurement, and quality assurance & inspection applications make up the worldwide machine vision market. The quality assurance & inspection category dominated the market during the research period and be the largest among all categories in the coming years. However, during the projected period, the identification category is expected to develop at the quickest rate. This is due to the numerous benefits and opportunities provided by technology on a global scale.

Insight by End User

The automotive, electronics and semiconductor, pharmaceuticals and chemicals, pulp and paper, food and beverage (packaging and bottling), postal and logistics, printing and labeling, and glass and metal sectors are key end users in the worldwide machine vision market. The automotive sector accounts for the largest market share, and it is anticipated to continue dominating the industry throughout the study period.

In the automobile sector, machine vision is mostly used for inspection tasks such as absence or presence verification, assembly confirmation, error proofing, and final inspection. In addition, dimensional gauging, robotic guidance, and testing automation are further uses of machine vision systems that fall under the category of gauge, measure, and guide applications.

Global Machine Vision Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2020 - 2024 |

|

Base Year Considered |

2025 |

|

Forecast Period |

2026 - 2035 |

|

Market Size in 2025 |

U.S.D. 9.85 Billion |

|

Revenue Forecast in 2035 |

U.S.D. 14.8 Billion |

|

Growth Rate |

6.2% |

|

Segments Covered in the Report |

By Offering, By Product, By Application, By End User. |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and the Rest of the World |

Industry Dynamics

Machine Vision Market Growth Drivers

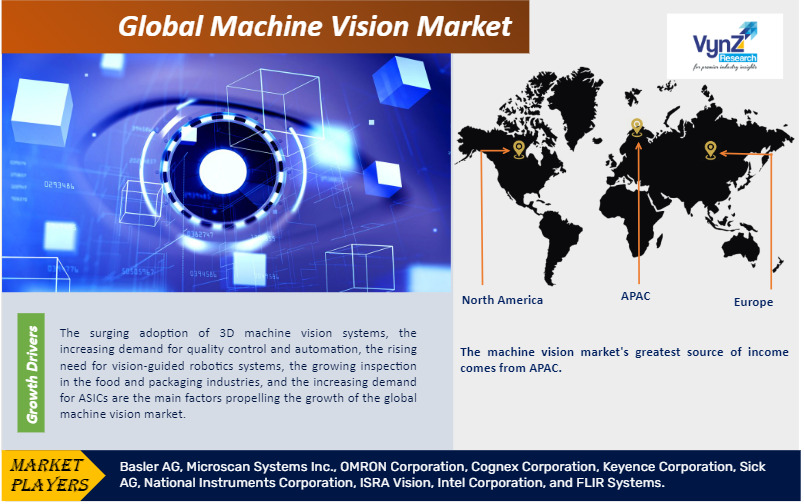

The surging adoption of 3D machine vision systems, the increasing demand for quality control and automation, the rising need for vision-guided robotics systems, the growing inspection in the food and packaging industries, and the increasing demand for ASICs are the main factors propelling the growth of the global machine vision market.

Globally, manufacturers want to boost their investments in automation following COVID-19. Additionally, as companies have come to understand the value of automated quality assurance in manufacturing processes, the demand for this technology has grown. The COVID-19 epidemic has accelerated the deployment of automation since it requires fewer human interventions in the process. This broadens the perception of machine vision as a necessary component of processes for developing long-term automation.

Machine Vision Market Challenges

The biggest challenge for machine vision producers is likely a lack of adaptable machine vision solutions and a shortage of experienced workers in production facilities.

Machine Vision Market Opportunities

The market offers several opportunities to players, due to the following reasons:

• Increasing need for machine vision applications of artificial intelligence (AI)

• Rising production of hybrid and electric vehicles

• Government programs to advance technology connected to AI

Machine Vision Market Geographic Overview

Geographically, the machine vision market's greatest source of income comes from APAC. In comparison to other regions, the APAC countries particularly China, Japan, Taiwan, South Korea, and India, are experiencing a growth in the usage of machine vision products and solutions. Moreover, the APAC machine vision market is projected to expand more quickly, due to the rising R&D expenditures as well as expanding manufacturing and electronics sectors.

Machine Vision Market Competitive Insight

Some of the key players operating in the global machine vision market are Basler AG, Microscan Systems Inc., OMRON Corporation, Cognex Corporation, Keyence Corporation, Sick AG, National Instruments Corporation, ISRA Vision, Intel Corporation, and FLIR Systems.

Basler is a leading international supplier of products for computer vision applications, including lenses, frame grabbers, cameras, lighting and image processing software.

Microscan is a global leader in technology for precision data acquisition and control solutions serving a wide range of automation and OEM applications.

Recent Development by Key Players

OMRON Corporation has launched the Data Solution Business Headquarters. The DSB will not only expand business in the healthcare domain but also identify opportunities for data solution business in other domains, such as industrial automation and social solution domains and establish specialized organizations to advance their business development and market implementation, to ultimately help solve social challenges through data solutions.

Cognex Corporation acquired Moritex Corporation. Cognex is a global manufacturer of machine vision systems and products, including sensors, bar code readers, software, and other tools. Moritex, also a global presence, produces machine vision products such as high-spec lenses and industrial lighting solutions; it also produces medical and cosmetic equipment.

Forecast Parameters

• Identifying variables and establishing market impact.

• Establishing market trends regionally.

• Analyzing opportunities and market penetration rates by understanding product commercialization, and regional expansion.

• Analyzing demand and supply trends and changes in industry dynamics to establish future growth.

• Analyzing sustainability strategies adhered to by market participants in an attempt to determine the future course of the market.

• Analyzing historical market trends and super-imposing them on the current and future variables to determine year-on-year trends.

• Understanding adoption, development, distribution, and regulatory framework.

Data Validation

• Estimated and forecasted data was validated through industry experts.

• Apart from industry experts, data triangulation methods were used for validation.

• Bottom-up and top-down approach has been used for estimation and forecast of market data, whereas the top-down approach was used for validation.

• Demand, as well as supply side surveys, were conducted in order to understand the industry dynamics and data validation.

Research Phases

.png)

Primary Research

VynZ Research conducts extensive primary research to understand the market dynamics, validate market data, and have key opinions from industry experts. The key profiles approached within the industry include CEO, CFO, CTO, President, Vice President, Product Managers, Regional Heads, and Others. Also, end user surveys comprising of consumers are also conducted to understand consumer behavior.

.png)

Source: VynZ Research

.png)

Source: VynZ Research

The Machine Vision Market report offers a comprehensive market segmentation analysis along with an estimation for the forecast period 2022–2030.

Segments Covered in the Report

- By Offering

- Hardware

- Software

- By Product

- PC Based

- Smart Camera-Based

- By Application

- Quality Assurance and Inspection

- Positioning and Guidance

- Measurement

- Identification

- By End User

- Automotive

- Pharmaceuticals & Chemicals

- Electronics & Semiconductor

- Pulp & Paper

- Printing & Labeling

- Food & Beverage (Packaging and Bottling)

- Glass & Metal

- Postal & Logistics

- Others

Region Covered in the Report

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- U.K.

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia-Pacific (APAC)

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Rest of the World (RoW)

- Brazil

- Saudi Arabia

- South Africa

- U.A.E.

- Other Countries

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverable

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Machine Vision Market