Global Smart Factory Market - Analysis and Forecast (2025-2030)

Industry Insights by Technology (Distributed Control System [DCS], Programmable Logic Controller [PLC], Manufacturing Execution System [MES], Enterprise Resource Planning [ERP], Supervisory Control and Data Acquisition [SCADA], Plant Asset Management [PAM], Human–Machine Interface [HMI], Product Life Cycle Management [PLM]), by Component (Sensors, Industrial Robots, Machine Vision Systems, Industrial 3D Printing), by Application (Automotive, Aerospace & Defense, Food & Beverage, Electrical & Electronics, Energy & Power)

| Status : Published | Published On : Jan, 2024 | Report Code : VRSME9022 | Industry : Semiconductor & Electronics | Available Format :

|

Page : 160 |

Global Smart Factory Market - Analysis and Forecast (2025-2030)

Industry Insights by Technology (Distributed Control System [DCS], Programmable Logic Controller [PLC], Manufacturing Execution System [MES], Enterprise Resource Planning [ERP], Supervisory Control and Data Acquisition [SCADA], Plant Asset Management [PAM], Human–Machine Interface [HMI], Product Life Cycle Management [PLM]), by Component (Sensors, Industrial Robots, Machine Vision Systems, Industrial 3D Printing), by Application (Automotive, Aerospace & Defense, Food & Beverage, Electrical & Electronics, Energy & Power)

Smart Factory Market Overview

The Smart Factory Market is expected to grow progressively at a CAGR of 10.1% during the forecast period from USD 152.0 billion to USD 247.0 billion by 2030.

Smart factories refer to the revolution optimization of the manufacturing process using sophisticated technologies such as AI, IoT, and robotics. These technologies facilitate predictive maintenance with real-time monitoring of the production process and also help in adaptive production. Overall, smart factories improve the efficiency of production and the quality of goods produced, offering more flexibility and digitization. It links every stage of the production process, streamlining the process to reduce delays or downtime and wastage of materials. It also helps businesses to be agile and adapt to ever-changing demands and market trends.

Smart Factory Market Segmentation

Insight by Technology

The Smart Factory market is divided by technologies into distributed control systems (DCS), product lifecycle management (PLM), programmable logic controllers (PLC), manufacturing execution systems (MES), enterprise resource planning (ERP), supervisory control and data acquisition (SCADA), plant asset management (PAM), and human-machine interface (HMI). Out of these segments, MES will dominate the market during the forecast period.

Insight by Component

According to components, the Smart Factory market is divided into sensors, machine vision systems, industrial robots, and industrial 3D printing segments. Out of these segments, the industrial robotics segment is expected to register the highest growth during the forecast period due to the ability to improve smart manufacturing procedures. This will result in higher productivity and lower errors. Other factors like supportive government initiatives, shortage of skilled labor, and collaborative efforts by corporations and the public are also driving growth. Furthermore, the industrial 3D printing market will also grow due to higher adoption in the aerospace, defense, semiconductor, electronics, automotive, and food and beverage sectors.

Insight by Industry Verticals

The Smart Factory market is divided by industry verticals into automotive, electronics, pharmaceuticals, food and beverage segments. Among these segments, the automotive industry will grow more due to higher demand, meticulous manufacturing, and integration of advanced robotics and other technologies like IoT and AI. This enhances the quality, efficiency, and flexibility which drive the market growth.

Insight by Company Size

Divided by size, the Smart Factory market segmentation includes small and medium-sized enterprises (SMEs) and large enterprises, where the latter is expected to dominate due to substantial resources, better infrastructure, higher budget and skilled labor. They are the early adopters of cutting-edge manufacturing technologies, which drives their expansion.

Insight by Production Process

The different production processes divide the Smart Factory market into discrete manufacturing and process manufacturing, where the former dominates the market and is expected to grow in the forecast period due to repetitive and structured production processes, increasing adoption of digital twins, AI-powered predictive maintenance, and collaborative robots that improves agility and productivity.

Insight by Maturity of Adoption

The Smart Factory market is also segregated by maturity of adoption into early adopters and late adopters. Out of the two, the early adopters dominate the market due to the competitive edge awareness of the businesses of the strategic significance of digital transformation for optimization of operations, cost reduction, and better product delivery.

Insight by Integration Levels

The Smart Factory market is categorized by the integration levels into fully integrated systems and modular solutions. Among these, the fully integrated segment dominates the market. It will grow due to higher demand for comprehensive end-to-end solutions to enhance manufacturing operations, interoperability standards developments, adoption of cloud computing and edge computing.

Global Smart Factory Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2020 - 2024 |

|

Base Year Considered |

2025 |

|

Forecast Period |

2026 - 2035 |

|

Market Size in 2025 |

U.S.D. 152.0 Billion |

|

Revenue Forecast in 2035 |

U.S.D. 247.0 Billion |

|

Growth Rate |

10.1% |

|

Segments Covered in the Report |

By Technology, By Component, By Industry Verticals, By Company Size, By Production Process, By Maturity of Adoption, and By Integration Levels |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and the Rest of the World |

Industry Dynamics

Smart Factory Industry Trends

There is a growing trend for leveraging artificial intelligence (AI) and machine learning algorithms in smart factories. This optimizes production process operations and improves decision-making abilities to meet predicting maintenance requirements. The Internet of Things (IoT) plays a crucial role in allowing smart factories to integrate communication and connectivity seamlessly into different systems and devices, which enhances real-time monitoring and better control over manufacturing processes. The growing emphasis on cybersecurity to protect intellectual property, sensitive information, and data has also been noticed, as has the increase in the measures to protect interconnected production systems from cyber threats and attacks. The growing adoption of additive manufacturing and 3D printing in smart factories is also noticed to facilitate on-demand production, prototyping and customization of parts. This results in cost savings and higher efficiency. Digital twin technology is adopted extensively in these factories to promote optimization, simulation, and predictive maintenance. Furthermore, smart factories are also prioritizing sustainability initiatives to reduce impacts on the environment by applying eco-friendly manufacturing applications, improving energy usage, and lowering waste generation.

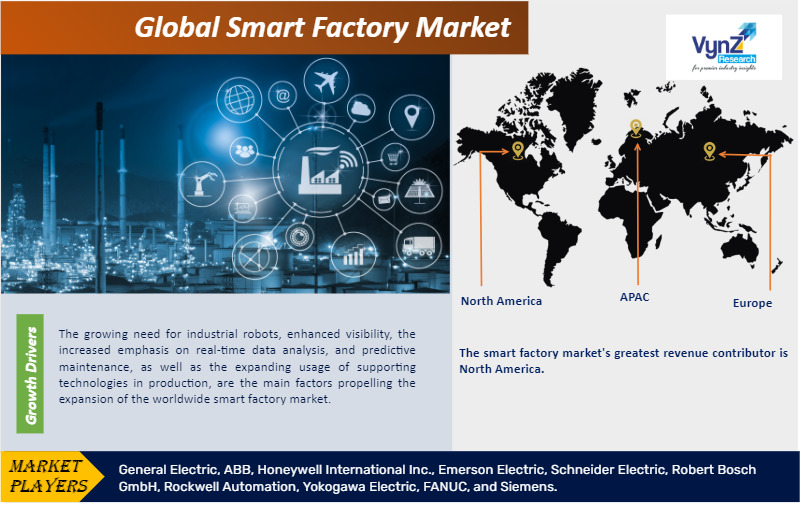

Smart Factory Market Growth Drivers

Ongoing advancements in technology and robotics improve efficiency in production and cost-effectiveness. The growth in consumer demand for personalized products results in higher adoption of flexible production, which enables rapid personalization and lowers time to market, driving market growth. Also, government initiatives support the promotion of Industry 4.0, which in turn brings in larger investments in smart factory technologies fueling growth. It is also attributed to integration of AR and VR in training programs, productivity, maintenance, operations, and management. Furthermore, the rise in environmental awareness among the users results in higher adoption of green practices in smart factories to reduce energy consumption and waste, drives growth. The rapid expansion of IIoT also facilitates growth as it helps in data collection and interpretation in real-time, which guarantees operational optimization.

Smart Factory Market Challenges

Security due to the use of specific technologies like blockchain is the chief obstacle that hinders the growth of the smart factory market worldwide.

Smart Factory Market Opportunities

However, growth opportunities are presented by the enduring developments made in 3D printing technology along with the better prospects offered by concerted robotics applications.

Smart Factory Market Geographic Overview

North America dominates the market in terms of revenue share of the smart factory market mainly due to the higher adoption of supply chain and intelligent manufacturing technologies across several industries in this region. It is also attributed to the significant rise in demand for automated and robotic systems to organize operational activities and meet the ever-rising demand and the growing demand for more technologically advanced manufacturing processes.

In the APAC region, significant growth is expected in the forecast period due to tech developments, rapid industrialization, growth of Industry 4.0 practices, and higher prioritization of smart manufacturing technologies in developing countries like China, Japan, and South Korea. Also, the higher demand for smart factory solutions in the automotive, electronics, and manufacturing sectors, along with supportive government initiatives and growing investments in infrastructure, further promises market growth in this region.

Smart Factory Market Competitive Insight

Emerson focuses on smart manufacturing technologies, as it grows its industrial IoT ecosystem and it becomes increasingly important for businesses to update their operations in order to improve business outcomes and pay back their investment.

Schneider's Smart Factory Program, which integrates IoT technologies in manufacturing facilities, buildings, and offices, focuses on industrial automation. By using agile management, energy efficiency, asset performance management, and process efficiency, Schneider has adopted digital transformation to make its factories smart.

Some of the major companies competing in the worldwide smart factory market include General Electric, ABB, Honeywell International Inc., Emerson Electric, Schneider Electric, Robert Bosch GmbH, Rockwell Automation, Yokogawa Electric, FANUC, and Siemens.

Recent Development by Key Players

GE Digital improved CIMPLICITY and Tracker software in March 2021. These updates help operators make crucial decisions and increase productivity. To precisely monitor and manage operations, CIMPLICITY HMI/SCADA offers client-server visualization. Tracker, a component of GE Digital's Proficy Manufacturing Execution Systems (MES) offering, automates routing and sequencing to shorten the time to market, lower the risk of a warranty or recall, and support lean operations and building something correctly the first time.

In March 2021, Stratasys unveiled a new 3D printer that enables dental labs the efficiency of 3D printing and the accuracy and realism of PolyJet. The only multi-material dental 3D printer that enables technicians to load mixed trays of dental components is the J5 DentaJet.

As part of ETH's RobotX program, ABB and ETH Zurich increased their collaboration in robotics research in March 2021. The goal of the RobotX program, which was introduced in 2019, is to establish ETH as a pioneer among institutions conducting robotics research. The project will have the assistance of ABB's Robotics and Discrete Automation division.

Beginning in March 2021, clients of Xometry's worldwide custom manufacturing marketplace will have access to a number of new high-performance nylon material alternatives thanks to a collaboration between Stratasys and Xometry. Customers of Xometry, ranging from small businesses to Fortune 100 corporations, can now take advantage of Stratasys Direct's extensive knowledge and sizable manufacturing capabilities in SLS 3D printing.

Salesforce (NYSE: CRM) and Siemens announced a strategic alliance in June 2020 to create a new workplace technology suite that will assist businesses worldwide in securely reopening and delivering the future of physical workplaces. The collaboration will bring together Siemens' Smart Infrastructure products, such as Comfy and Enlighted, and Salesforce's Work.com, driven by Customer 360, to coordinate the procedures, individuals, and resources necessary to develop secure, connected workplaces in the future.

Forecast Parameters

- - Identifying variables and establishing market impact.

- - Establishing market trends regionally.

- - Analyzing opportunities and market penetration rates by understanding product commercialization, and regional expansion.

- - Analyzing demand and supply trends and changes in industry dynamics to establish future growth.

- - Analyzing sustainability strategies adhered to by market participants in an attempt to determine the future course of the market.

- - Analyzing historical market trends and super-imposing them on the current and future variables to determine year-on-year trends.

- - Understanding adoption, development, distribution, and regulatory framework.

Data Validation

- - Estimated and forecasted data was validated through industry experts.

- - Apart from industry experts, data triangulation methods were used for validation.

- - Bottom-up and top-down approach has been used for the estimation and forecast of market data, whereas the top-down approach was used for validation.

- - Demand, as well as supply side surveys, were conducted in order to understand the industry dynamics and data validation.

Research Phases

.png)

Primary Research

VynZ Research conducts extensive primary research to understand the market dynamics, validate market data, and have key opinions from industry experts. The key profiles approached within the industry include the CEO, CFO, CTO, President, Vice President, Product Managers, Regional Heads, and Others. Also, end user surveys comprising of consumers are also conducted to understand consumer behavior.

.png)

Source: VynZ Research

.png)

Source: VynZ Research

The Cyber Security Market report offers a comprehensive market segmentation analysis along with an estimation for the forecast period 2025–2030.

Segments Covered in the Report

- By Technology

- Distributed Control System (DCS)

- Programmable Logic Controller (PLC)

- Manufacturing Execution System (MES)

- Enterprise Resource Planning (ERP)

- Supervisory Control and Data Acquisition (SCADA)

- Plant Asset Management (PAM)

- Human–Machine Interface (HMI)

- Product Life Cycle Management (PLM)

- By Component

- Sensors

- Industrial Robots

- Machine Vision Systems

- Industrial 3D Printing

- By Application

- Automotive

- Aerospace & Defense

- Food & Beverage

- Electrical & Electronics

Region Covered in the Report

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- U.K.

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia-Pacific (APAC)

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Rest of the World (RoW)

- Brazil

- Saudi Arabia

- South Africa

- U.A.E.

- Other Countries

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverable

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Smart Factory Market