Global Machine Condition Monitoring Market – Analysis and Forecast (2025-2030)

Industry Insight by Offering (Hardware (Vibration Sensors, Infrared Sensors, Spectrometers, Ultrasound Detectors, Spectrum Analyzers, Corrosion Probes, and Others) and Software (Data Integration, Diagnostic Reporting, Order Tracking Analysis, and Parameter Calculation)), by Monitoring Techniques (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, and Motor Current Analysis), by Deployment Type (On-Premises and Cloud), by Monitoring Process (Online Condition Monitoring and Portable Condition Monitoring), by Industry (Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Aerospace & Defense, Food & Beverages, Marine, and Others), and Geography (U.S., Canada, Germany, U.K., France, China, Japan, India, and Rest of the World)

| Status : Published | Published On : Jul, 2024 | Report Code : VRSME9103 | Industry : Semiconductor & Electronics | Available Format :

|

Page : 250 |

Global Machine Condition Monitoring Market – Analysis and Forecast (2025-2030)

Industry Insight by Offering (Hardware (Vibration Sensors, Infrared Sensors, Spectrometers, Ultrasound Detectors, Spectrum Analyzers, Corrosion Probes, and Others) and Software (Data Integration, Diagnostic Reporting, Order Tracking Analysis, and Parameter Calculation)), by Monitoring Techniques (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, and Motor Current Analysis), by Deployment Type (On-Premises and Cloud), by Monitoring Process (Online Condition Monitoring and Portable Condition Monitoring), by Industry (Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Aerospace & Defense, Food & Beverages, Marine, and Others), and Geography (U.S., Canada, Germany, U.K., France, China, Japan, India, and Rest of the World)

Machine Condition Monitoring Market Overview

The Global Machine Condition Monitoring Market is poised to experience significant growth, with an estimated rise from USD 2.8 billion in 2023 to USD 4.6 billion by 2030. This growth is projected to be driven by a robust compound annual growth rate (CAGR) of 7.2% during the forecast period from 2025 to 2030. Machine condition monitoring is the process of assessing and analyzing the condition of machines to predict mechanical wear and potential failures.

The expanding wireless communication in heating, ventilation, and air conditioning (HVAC) systems is expected to be a major contributor to the market's expansion. As the world's population continues to grow, there will be a heightened demand for HVAC systems, which in turn will necessitate monitoring the health of related equipment to ensure smooth system operation. This increased requirement for machine condition monitoring will fuel the market's growth.

Businesses must prioritize proper maintenance and rely on reliable equipment to position themselves for the anticipated surge in demand for goods and services. Implementing predictive maintenance techniques will enable them to recover quickly from failures and generate profits. Consequently, the machine condition monitoring market will be stimulated by the mounting digitalization and substantial growth in various industry verticals such as oil and gas, defense, manufacturing, automotive, aerospace, food and beverage, and marine industries.

The COVID-19 pandemic has moderately impacted the machine condition monitoring market owing to disruption in the supply chain and restrictions on the adoption of hardware components like sensors and detectors in various applications. Not all semiconductor companies, on the other hand, are seeing a slowdown in growth, since remote monitoring of production processes has allowed them to continue working even during lockdowns. The market for condition monitoring systems and solutions is expected to grow in the next years, with the market recovering during that time.

Machine Condition Monitoring Market Segmentation

Insight by Offering

Based on offering, the global machine condition monitoring market is bifurcated into hardware and software. Hardware is further divided into Vibration Sensors (accelerometers, proximity probes, and tachometers), infrared sensors (thermal infrared sensors and quantum infrared sensors), spectrometers (infrared spectrometers, ultraviolet spectrometers, atomic spectrometers, and mass spectrometers), ultrasound detectors (sound pressure meters, stethoscopes, and ultrasonic leak detectors), spectrum analyzers (swept spectrum analyzers and real-time spectrum analyzers), corrosion probes, and others. software is further divided into data integration, diagnostic reporting, order tracking analysis, and parameter calculation.

The hardware segment dominates the market owing to the rising demand for hardware parts like vibration sensors and analyzers, ultrasound detectors, corrosion probes, spectrum analyzers, etc. that play an important role in condition monitoring systems and provide information related to machine conditions in advance. This information can be used to drive maintenance programs for machine and prevents expensive downtime.

Insight by Monitoring Techniques

Based on monitoring techniques, the global machine condition monitoring market is segregated into vibration monitoring, thermography, oil analysis, corrosion monitoring, ultrasound emission, and motor current analysis. Thermography dominates the market as it is extensively deployed in several industry verticals like military, medical, electrical, or mechanical engineering, process monitoring, energy evaluations, etc.

Insight by Deployment Type

Based on deployment type, the global machine condition monitoring market is bifurcated into on-premises and cloud. The cloud-based monitoring segment is anticipated to have substantial growth as it offers 24/7 service, enhances scalability and speed, and improves IT security. Also, the increased adoption of software as a service (SaaS) applications by enterprises will propel the growth of the market.

Insight by Monitoring Process

Based on the monitoring process, the global machine condition monitoring market is bifurcated into online condition monitoring and portable condition monitoring. Online condition monitoring contributes the largest share of the market as it provides real-time plant data to operators and works in industries where 24-hour production is needed.

Insight by Industry

Based on industry, global machine condition monitoring is segmented into oil & gas, power generation, metals & mining, chemicals, automotive, aerospace & defense, food & beverages, marine, and others. Oil & gas is anticipated to hold the largest share in the market owing to the variation in prices, there is a need to minimize operational costs and reduce the possibility of machine downtime in oil & gas plants.

There is a need to implement condition monitoring systems and solutions in order to keep critical assets operating efficiently and prevent downtime. Furthermore, the growing need for online condition-monitoring solutions is likely to propel the machine condition-monitoring market in the oil and gas industry even further.

Global Machine Condition Monitoring Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2020 - 2024 |

|

Base Year Considered |

2025 |

|

Forecast Period |

2026 - 2035 |

|

Market Size in 2025 |

U.S.D. 2.8 Billion |

|

Revenue Forecast in 2035 |

U.S.D. 4.6 Billion |

|

Growth Rate |

7.2% |

|

Segments Covered in the Report |

By Offering, By Monitoring Techniques, By Deployment Type, By Monitoring Process, By Industry |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

Machine Condition Monitoring Industry Trends

Machine condition monitoring market expansion would be fueled by the adoption of machine learning, big data analytics, and a parallel processing framework. Because of its ability to process large amounts of data, big data analytics has boosted the analysis of data supplied by condition monitoring systems.

Machine learning enables simple machine performance benchmarking, data transparency, and efficient collaboration among multiple condition monitoring system operations. Companies can minimize their overall cost of ownership of assets and run their businesses more efficiently with big data-enabled condition monitoring. These trends will anticipate propelling the machine condition monitoring market.

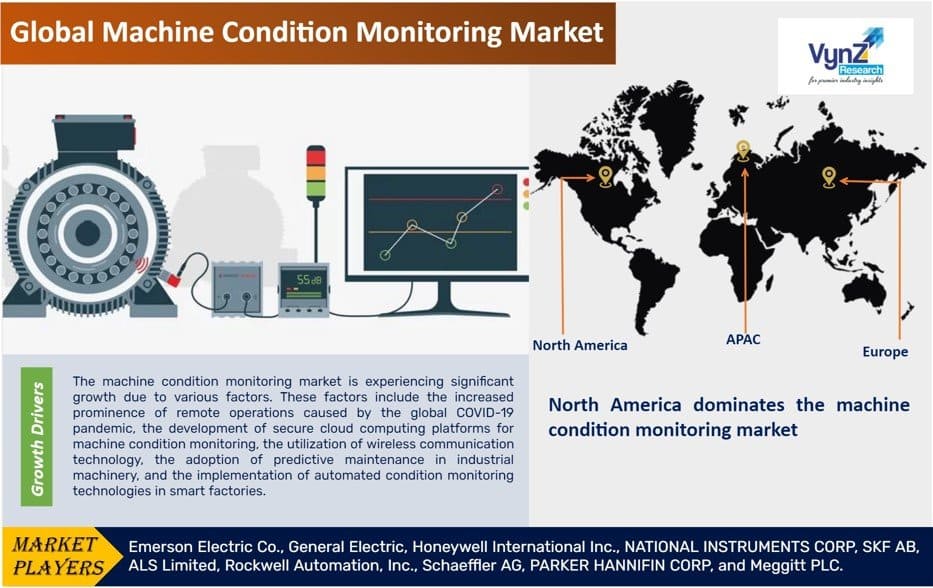

Machine Condition Monitoring Market Growth Drivers

The machine condition monitoring market is experiencing significant growth due to various factors. These factors include the increased prominence of remote operations caused by the global COVID-19 pandemic, the development of secure cloud computing platforms for machine condition monitoring, the utilization of wireless communication technology, the adoption of predictive maintenance in industrial machinery, and the implementation of automated condition monitoring technologies in smart factories. These factors have collectively contributed to the market's growth.

One of the key drivers of this growth is the increasing demand for vibration monitoring systems. These systems are utilized to measure oscillations in components such as belts, gears, bearings, drive motors, and other elements. As infrastructure development continues, the need for vibration monitoring systems is also expanding, further fueling the growth of the machine condition monitoring market.

Machine condition monitoring offers numerous advantages. Firstly, it ensures safety by detecting potential issues and preventing failures. Secondly, it helps in reducing maintenance costs by enabling proactive maintenance instead of reactive repairs.

Additionally, it increases operational efficiency by identifying inefficiencies and optimizing machine performance. Moreover, machine condition monitoring enhances machine reliability and availability, thereby minimizing downtime. Lastly, it extends the machine's lifespan by identifying maintenance needs and eliminating the chances of critical failures.

So, The machine condition monitoring market is witnessing substantial growth due to factors like the increasing prominence of remote operations, secure cloud computing platforms, wireless communication technology, predictive maintenance adoption, and automated condition monitoring technologies. The market is further driven by the growing demand for vibration monitoring systems and the various advantages provided by machine condition monitoring, including safety assurance, cost reduction, operational efficiency improvement, enhanced reliability and availability, and prolonged machine lifespan.

Machine Condition Monitoring Market Challenges

The challenges faced by industry players include increased short-term investment required, lack of skilled resources for data analysis, mounting reliability issues about predicting the capabilities of machine condition monitoring technology, accessibility of automated and clod solutions for machine condition monitoring in remote areas is tough, and equipment required for condition monitoring is expensive.

Furthermore, depending on the environment, condition monitoring sensors may not survive, therefore machine maintenance times are uncertain. This factor is posing a threat to the market's expansion.

Machine Condition Monitoring Market Opportunities

Within the projected period, technological advancements such as low-cost improved machine condition monitoring systems, process, and rapid processing functionalities are expected to generate new opportunities for market growth.

Machine Condition Monitoring Market Geographic Overview

North America dominates the machine condition monitoring market owing to the presence of many industrial sectors in the US, Mexico, and Canada. Furthermore, the US has well-established and emerging machine condition monitoring solution providers, stringent quality control in the chemicals, oil & gas, food & beverage industry will accelerate the growth in the region.

However, because monitoring hardware has a longer lifespan, demand for it is confined to new manufacturing operations. This is likely to slow the region's machine condition monitoring market's year-on-year growth.

Machine Condition Monitoring Market Competitive Insight

The industry players are entering into organic and inorganic strategies like a product launch, R&D activities, acquisitions to sustain themselves in the machine condition monitoring market. The manufacturers are increasing their productivity with high efficiency and are emphasizing evaluating the health and operability of each asset.

Emerson's condition monitoring systems are tailored to the application and criticality of machines, provide reliable data for accurate machinery diagnosis. The condition monitoring solution offered includes Route-Based Vibration Analyzers, Wireless IIoT Solutions, Online Condition Monitoring, Integrated Condition Monitoring for Power and Water Applications, Machinery Protection with Embedded Prediction, and Machinery Health for Power Industry.

ALS is a global leader in providing laboratory testing, inspection, certification and verification solutions.

Some of the major players operating in the machine condition monitoring market include Emerson Electric Co., General Electric, Honeywell International Inc., NATIONAL INSTRUMENTS CORP, SKF AB, ALS Limited, Rockwell Automation, Inc., Schaeffler AG, PARKER HANNIFIN CORP, and Meggitt PLC.

Recent Developments by Key Players

Rockwell Automation, Inc., the world's largest company dedicated to industrial automation and digital transformation, is collaborating with Drillmec, a global on- and offshore drilling specialist based in Italy that is developing new, innovative storage technologies.

Schaeffler AG (German company) and Vitesco Technologies, a leader in electrification solutions for sustainable mobilitycollaborated. The planned merger will lead to restructuring with four specialized divisions.

"With the resulting company, which will now be larger, we will be able to use and contribute our knowledge and experience even better and join forces to take big steps towards cleaner mobility,"

The Machine Condition Monitoring Market Report offers a comprehensive market segmentation analysis along with an estimation for the forecast period 2025–2030.

Segments Covered in the Report

- By Offering

- Hardware

- Vibration Sensors

- Infrared Sensors

- Spectrometers

- Ultrasound Detectors

- Spectrum Analyzers

- Corrosion Probes

- Others

- Software

- Data Integration

- Diagnostic Reporting

- Order Tracking Analysis

- Parameter Calculation

- Hardware

- By Monitoring Techniques

- Vibration Monitoring

- Thermography

- Oil Analysis

- Corrosion Monitoring

- Ultrasound Emission

- Motor Current Analysis

- By Deployment Type

- On-Premises

- Cloud

- By Monitoring Process

- Online Condition Monitoring

- Portable Condition Monitoring

- By Industry

- Oil & Gas

- Power Generation

- Metals & Mining

- Chemicals

- Automotive

- Aerospace & Defense

- Food & Beverages

- Marine

- Others

Region Covered in the Report

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- U.K.

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia-Pacific (APAC)

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Rest of the World (RoW)

- Brazil

- Saudi Arabia

- South Africa

- U.A.E.

- Other Countries

.png)

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverable

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Machine Condition Monitoring Market